ALCAS METAL SANAYİ ANONİM ŞİRKETİ

Istanbul / Türkiye

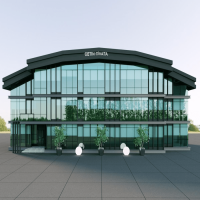

Silicone Facade

Structural silicone facade is an aluminum curtain wall system. It is also called a glazing system because it is not visible in the outer appearance of aluminum profiles. Alcas Aluminum profile systems preferred by Nur Cephe in production have jx and jy values that can provide the static calculation value required for silicone facade profiles. Alcas Profiles discharge condensation and rain water from the system thanks to the existing condensation channels. This reduces the chance of water getting in. Structural silicone facade carrier system; It is produced in middle and transom profiles with 2mm and 1.8mm wall thicknesses, 65mm and 150mm widths. Earthquake, building settlement, wind, storm etc. Transom profiles designed to withstand adverse conditions are not fixed to the middle profiles with screws, they are carried on male and female carriers. Thus, since the panel can move in case of expansion or earthquake, it does not shrink and minimizes the risk of glass breakage. Sliding, transom, paneled and glazed bar profiles are all flexible. In the system, the glasses are not attached directly to the panel profile, but to the anodized bar profile with a channel on the panel. Thus, since it is not fixed to the glass panel profile at the time of expansion and is stretchable, it eliminates the risk of breakage and cracking. Anodized surface is required for gluing static painted facade profiles. Since this bar profile is independent, it can be anodized. This detail also makes the system more reliable. While the AF50E system carries all the features of the AF50S structural silicone system, it provides economic advantage and aesthetics since it does not require a cassette-panel system to carry the glasses. The system works with the U channel hidden behind the dehumidification bar between the double windows. . The U channel is fixed between the double glazing with a special double component silicone, and it is mounted on the transom and mullion through the screw channel thanks to the special clips from these channels. Horizontal and vertical joints 20 mm. and these joints are closed with specially designed silicone wick and silicone. The façade line is kept at a minimum distance thanks to the absence of a cassette panel system. Thanks to the internal-external corner adapters and clips specially designed for the system, faster and cleaner turns are provided both in production and assembly. Thanks to the plastic adapter attached to the center batten and transom mounting screw channels, a system with a low heat transmission coefficient has been created. The system discharges the condensed and leaking water from the discharge channels in the horizontal and vertical carrier system. With all these features, the AF50 E system is a robust and superior system, while being economical by saving material and labor. By using the carriers of the AF50 E system, high thermal insulation value is obtained in the cover system and heat transfer is prevented by placing specially designed heat barriers on the system. In this way, the system has provided energy savings that will bear its own cost over time.