ANADOLU MÜHENDİSLİK METALURJİ VE REFRAKTER SAN. VE TİC. LTD. ŞTİ.

Gaziantep / Türkiye

About Us

Anadolu Refrakter, established in 1988 in Gaziantep, is a global leader in the manufacture of refractory materials, providing advanced solutions for industries that require materials capable of withstanding extreme heat. Specializing in products for the iron and steel industries, Anadolu Refrakter also serves sectors such as glass, cement, petrochemicals, and power generation. With customers in Europe, Asia, Africa, and the Middle East, the company is committed to delivering innovative, high-quality products to meet the stringent demands of industrial applications.

Where are refractories used?

Refractories are critical in any industry that involves high temperatures. Anadolu Refrakter’s products are primarily used in:

- Iron and steel production: Ladle and tundish systems, converters, and furnaces.

- Cement and lime kilns: Essential for lining high-temperature kilns.

- Glass and ceramics: Furnace linings to handle molten materials.

- Petrochemical industry: Reactor linings and high-temperature processing equipment.

- Power generation: Boiler linings for handling extreme temperatures.

What are good refractories?

Good refractories are defined by their ability to withstand intense heat, maintain structural integrity, and resist chemical corrosion. Anadolu Refrakter excels in manufacturing:

- High thermal shock resistance materials.

- Low thermal conductivity products that provide effective insulation.

- Chemically stable refractories that resist slag, molten metal, and aggressive industrial chemicals.

Products:

Anadolu Refrakter offers a comprehensive range of refractory products designed for durability and performance:

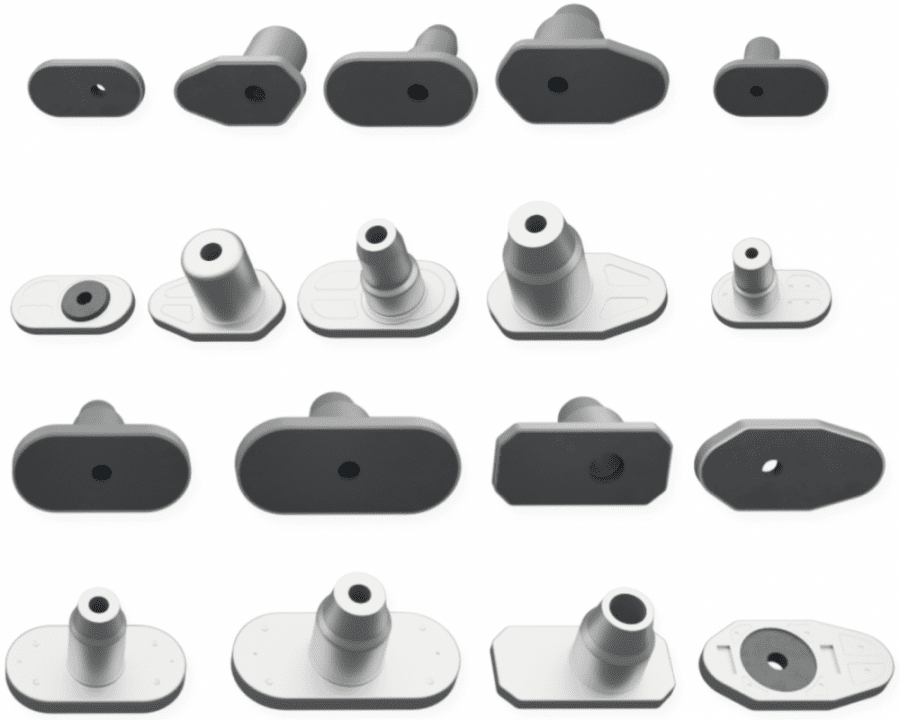

- Ladle slide plates and refractories: Control the flow of molten metal in steel-making ladles, ensuring precise handling.

- Ladle slide systems, tundish mechanisms, and spares: Provide superior control and functionality for molten steel handling.

- Tundish zirconia nozzles: Highly durable and heat-resistant for precise steel casting.

- Refractory mortars (Alumina, Magnesite): Provide excellent bonding and heat resistance for furnace linings.

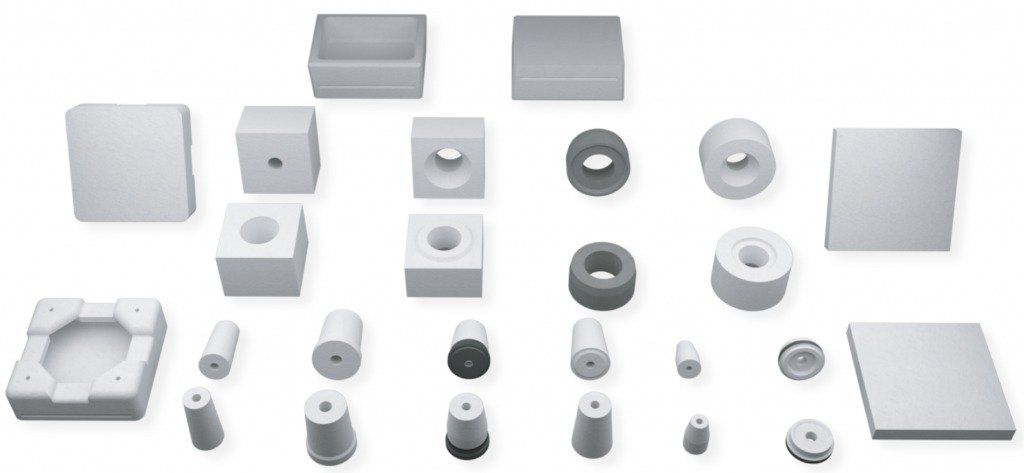

- Shaped refractories: Customized for specific industrial applications, including bricks and pre-formed shapes.

- Conductive hot repair mortar for DC-EAF: Used for in-situ repairs in DC Electric Arc Furnaces, maintaining efficiency without shutdowns.

- Slag cutting dart for steel converters: Controls slag flow, essential in converter operations.

- Tundish flow control system: Ensures smooth and controlled steel flow in the casting process.

- Ladle nozzle sand: Prevents blockage in ladle nozzles, ensuring operational consistency.

- Slide plate and nozzle sheets: Key components for maintaining steel flow systems.

What are the raw materials for refractories?

Anadolu Refrakter uses premium raw materials that define the quality of its products:

- Alumina (Al2O3): Known for its high melting point and thermal resistance, widely used in furnace linings and ladle systems.

- Silica (SiO2): Common in glass production and coke oven refractories.

- Magnesia (MgO): A core material in basic refractories, especially in the steel industry.

- Zirconia (ZrO2): Highly resistant to thermal shock and corrosion, used in tundish nozzles and high-temperature applications.

- Carbon-based refractories: Used in environments requiring superior thermal shock resistance, such as steel production.

What is the refractories market?

Anadolu Refrakter operates within the global refractories market, which is driven by the demand for materials that can withstand extreme temperatures in industrial processes. The primary consumers of refractories are the iron and steel industries, which account for more than 50% of global demand. Other significant markets include cement, glass, petrochemical, and power generation industries. Anadolu Refrakter continues to expand its reach by providing high-quality, durable, and customized refractory solutions for global clients.