BERK ÇELİK CIVATA SAN. A.Ş.

Gaziantep / Türkiye

Advanced Metal Casting and Molding Facility Overview

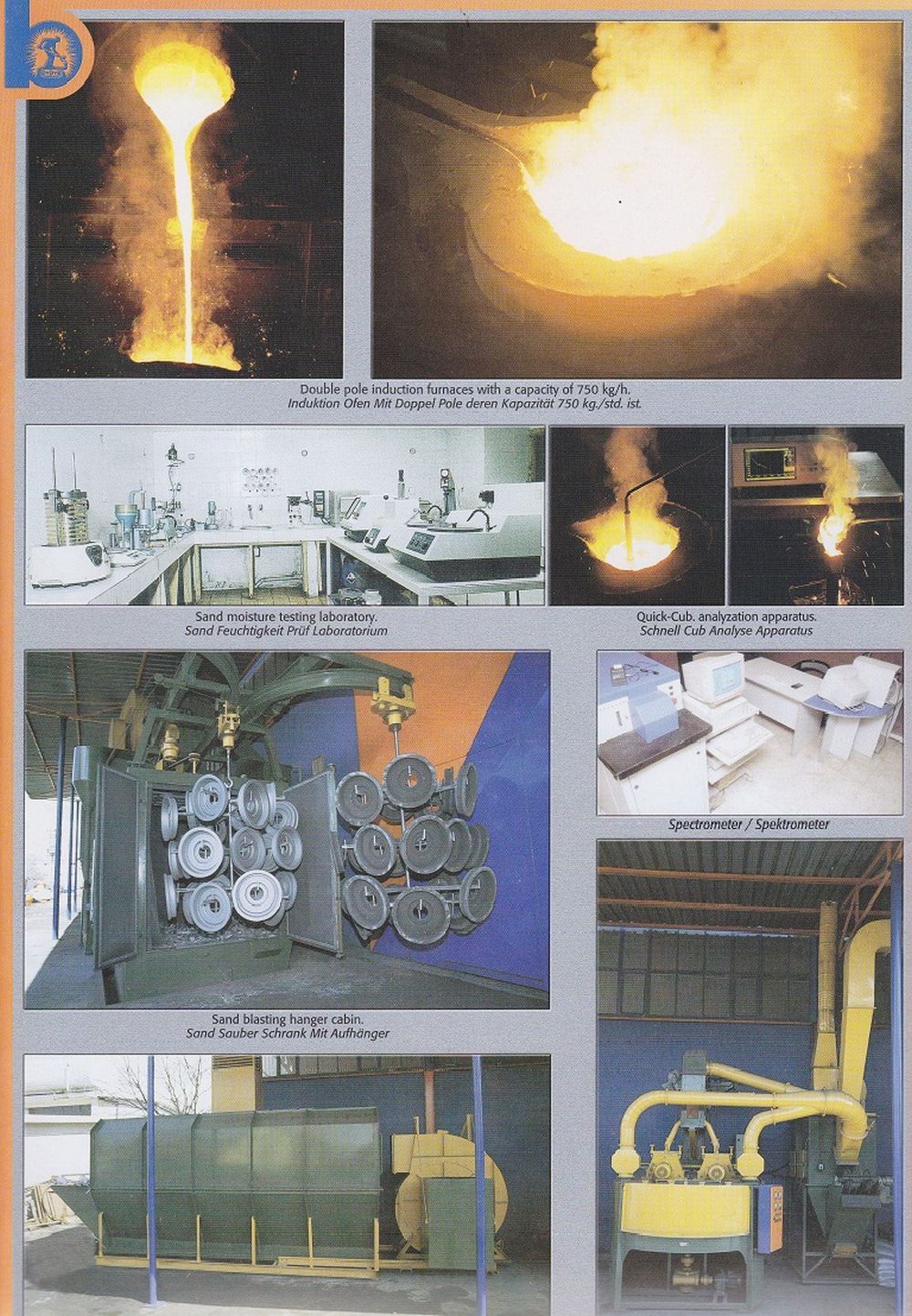

Advanced Metal Casting and Molding Facility Overview Double Pole Induction Furnaces: With a capacity of 750 kg/h, these furnaces efficiently melt metal for casting, providing high productivity and precision in metalworking applications. Sand Moisture Testing Laboratory: This facility ensures the proper moisture levels in the sand used for casting molds, essential for achieving consistent and high-quality casting results. Quick-Cub Analysis Apparatus: This equipment is used for rapid analysis of molten metal to ensure its composition meets the required specifications before casting. Spectrometer: A critical tool for metal analysis, ensuring the exact chemical composition of the metal, which is crucial for producing high-quality cast components. Sand Blasting Hanger Cabin: Used for cleaning and preparing metal surfaces by blasting them with high-speed sand particles, ensuring smooth surfaces for further processes or finishing. This molding atelier is equipped to handle the complete process of metal casting, from material preparation to the final surface finishing, ensuring precise and reliable production of metal parts.