YEMMAK YEM MAKİNELERİ

Balıkesir / Türkiye

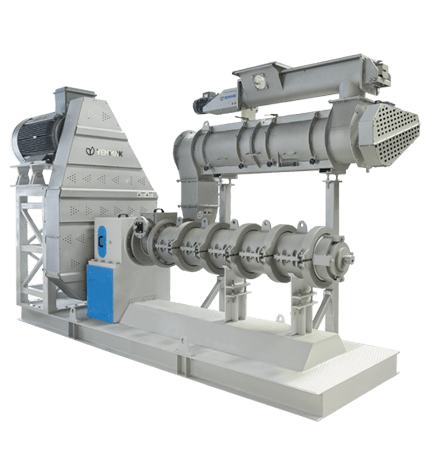

Corn Flattening Process Line

Corn Flattening Process Line The Corn Flattening Process Line is an advanced system designed for efficient corn flake production. It ensures high-quality flattening of corn kernels, providing uniform and consistent flakes ideal for both feed and food industries. This machine is specifically engineered to handle large volumes of corn while maintaining precision in flake thickness, ensuring optimal nutritional retention and product quality. Key Features: High-Efficiency Corn Flaking Rollers: Precisely designed rollers flatten corn kernels uniformly, improving the cooking and digestibility of flakes for feed production. Adjustable Flake Thickness: The system allows for flexible adjustment of flake thickness to meet specific product requirements, ensuring versatility in feed and food applications. Automated Control System: Advanced automation ensures consistent operation, minimizing the need for manual intervention and enhancing production efficiency. Energy-Efficient Design: The system is optimized for low energy consumption, reducing operational costs while maintaining high output. Benefits: Improved Digestibility: Flattened corn is easier for animals to digest, which is particularly beneficial in ruminant feed, improving feed conversion rates. Uniform Flakes: Ensures consistency in flake size and thickness, providing uniform quality for the end product. High-Capacity Processing: Designed for high throughput, this system is ideal for large-scale corn flaking operations in both feed mills and food processing plants. Applications: Animal Feed Production: The corn flattening process is critical in producing high-quality, digestible corn flakes used in ruminant and poultry feed. Food Industry: This line can also be used for producing corn flakes for human consumption, ensuring a consistent and high-quality product. With Yemmak's strong presence in the feed machinery market, the corn flattening process line integrates cutting-edge technology to deliver reliable, energy-efficient performance.