BOZOK MAKİNA MODEL HAVACILIK SAN.VE TİC. LTD.ŞTİ

Istanbul / Türkiye

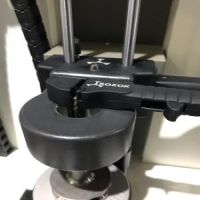

Shrink Fit Machine

A shrink fit machine is a machine that is used to assemble components with a shrink fit connection, which is a type of interference fit where one component is heated and expanded, and the other component is cooled and contracted, allowing the two components to be pressed together with a tight fit. Shrink fit machines are typically used to assemble components that require a high degree of accuracy and repeatability, such as in the aerospace, automotive, and precision manufacturing industries. They are also used in the repair and maintenance of equipment and machinery. To use a shrink fit machine, the operator first selects the appropriate size shrink fit mandrel, which is a tool that is used to hold the component being heated. The component is then placed on the mandrel and heated to a predetermined temperature, typically using an induction heating system. Once the component has reached the proper temperature, it is removed from the heating system and placed onto the fitting component, which has been cooled to a temperature that will cause it to contract. The two components are then pressed together, forming a tight fit. Shrink fit machines are highly precise and efficient, and they offer many advantages over other methods of assembly, such as increased accuracy, repeatability, and reliability. They are also faster and more efficient than traditional methods, such as press fits or threaded connections, and they require less maintenance and downtime. In terms of efficiency, shrink fit machines are generally considered to be highly efficient due to their precision and repeatability. They can assemble components with a high degree of accuracy and consistency, which can reduce waste and improve overall productivity. Additionally, shrink fit machines are typically faster and more efficient than other methods of assembly, such as press fits or threaded connections, which can further improve efficiency. As for the carbon footprint of shrink fit machines, it will depend on the specific design and energy usage of the machine. Induction heating systems, which are commonly used in shrink fit machines, are generally more efficient than other methods of heating, such as resistance heating or gas heating, and can help reduce the carbon footprint of the machine. However, the overall carbon footprint of a shrink fit machine will also depend on factors such as the energy source used to power the machine and the materials and processes involved in its manufacture and disposal. - User friendly with touch screen - Plug in cable ready to use - %50 reducing on energy consumption - Optimised heating andd cooling time for energy efficiency - Hybrid cooling (water and air cooling) - Up to Ø33 mm outer diamater of tool holder - 2,3 kWh for heating and 0,2 kWh for cooling