SATICI SATMAK MAKİNA SANAYİ TİCARET LİMİTED ŞİRKETİ

Istanbul / Türkiye

About Us

How is Sandblasting Done?

Sandblasting is a widely used surface treatment technique in various industries for cleaning, preparing, or texturing surfaces. The process involves propelling abrasive materials at high speed onto a surface to achieve the desired finish. Here is a step-by-step guide on how sandblasting is done:

1. Preparation

Material Selection: Choose the appropriate abrasive material for the job. Common materials include sand, glass beads, steel grit, and aluminum oxide.

Equipment Check: Ensure that the sandblasting machine, compressor, and other necessary equipment are in working order. Check hoses, nozzles, and other components for any wear or damage.

Protective Gear: Operators should wear protective equipment, including goggles, masks, gloves, and protective clothing, to safeguard against abrasive particles and dust.

2. Surface Preparation

Surface Cleaning: Remove any loose dirt, grease, and other contaminants from the surface to be blasted. This helps make the sandblasting process more effective.

Masking: Protect areas that should not be blasted by covering them with masking materials, such as tape or protective sheeting.

3. Sandblasting Process

Loading Abrasive Material: Load the chosen abrasive material into the sandblasting machine.

Pressure Adjustment: Adjust the pressure settings on the sandblasting machine according to the type of surface and abrasive material being used.

Blasting: Hold the sandblasting gun or nozzle at a specific distance from the surface and start blasting. Move the nozzle continuously to ensure even treatment of the entire surface. The operator controls the direction and speed of the abrasive stream to achieve the desired effect.

4. Post-Blasting

Cleaning: After sandblasting, remove any remaining abrasive material and dust from the surface. This can be done using compressed air or brushing.

Inspection: Examine the blasted surface to ensure it meets the required specifications. Check for uniformity and any missed spots. If necessary, repeat the sandblasting process.

5. Protective Coating (Optional)

Coating Application: Apply a protective coating, such as paint or sealant, to the blasted surface. This helps protect the surface from corrosion and enhances its appearance.

Tips for Effective Sandblasting

Maintain Consistent Distance: Keep a consistent distance between the nozzle and the surface to ensure even coverage.

Use Appropriate Pressure: Adjust the pressure based on the material and surface to avoid damage or inadequate cleaning.

Regular Equipment Maintenance: Regularly inspect and maintain the sandblasting equipment to ensure optimal performance and safety.

Sandblasting is a versatile technique that, when done correctly, provides efficient and effective surface treatment for various applications, from industrial cleaning to decorative texturing.

SATMAK Makina Product Range

Rollo Conveyor Sandblasting Machine: The Roller Conveyor Sandblasting Machine is used for surface preparation of sheet metal and profiles. Commonly used in metal processing plants, automotive production lines, and steel mills. Materials are continuously and automatically blasted using a conveyor system, enhancing surface quality.

Hanger Type Sandblasting Machine: The Hanger Type Sandblasting Machine is used for cleaning large and heavy parts. This machine allows parts to be blasted while hanging on hooks, providing 360-degree coverage. Widely used in steel construction, shipbuilding, and heavy industry sectors.

Compact Hanger Type Sandblasting Machine: The Compact Hanger Type Sandblasting Machine is designed for smaller, compact parts. Used in automotive parts production facilities, metal processing workshops, and various industrial applications. It provides high efficiency in small spaces.

Rubber Drum Sandblasting Machine: The Rubber Drum Sandblasting Machine is used for batch processing small parts. The machine tumbles parts inside the drum, ensuring uniform surface treatment. Ideal for automotive parts, foundries, and small metal parts.

Steel Tank Sandblasting Machine: The Steel Tank Sandblasting Machine is used for cleaning large steel tanks and vessels. This machine is used in steel production plants, chemical industry, and maintenance of storage tanks. Its thick and durable construction ensures long-lasting use.

Continuous Monorail Hanger Type Sandblasting Machine: The Continuous Monorail Hanger Type Sandblasting Machine provides continuous sandblasting for high-volume production lines. Parts are transported on a monorail and automatically blasted. Used in automotive factories, white goods production facilities, and large-scale metal processing lines.

Sandblasting and Painting Line: The Sandblasting and Painting Line combines sandblasting and painting processes. This integrated system performs surface preparation and coating in a single line. Used in metal processing plants, automotive industry, and steel construction companies.

Vertical Plate Sandblasting Machine: The Vertical Plate Sandblasting Machine is used for cleaning vertically positioned plates. Commonly used in the construction sector, shipbuilding, and large plate processing facilities. It provides high efficiency and fast processing.

Coil Sandblasting Machine: The Coil Sandblasting Machine is designed for blasting coiled sheets. Used in metal coating plants, automotive industry, and steel production lines. It allows continuous processing of coiled materials.

Calibrated Bar Sandblasting Machine: The Calibrated Bar Sandblasting Machine is used for cleaning calibrated bars. Commonly used in steel mills, machine manufacturing, and construction sectors. It provides high precision and smooth surface quality.

Manual Sandblasting Cabinet: The Manual Sandblasting Cabinet is used for manual blasting of small-scale and precise jobs. Widely used in workshops, maintenance and repair centers, and small production facilities. It offers complete control and flexibility to the user.

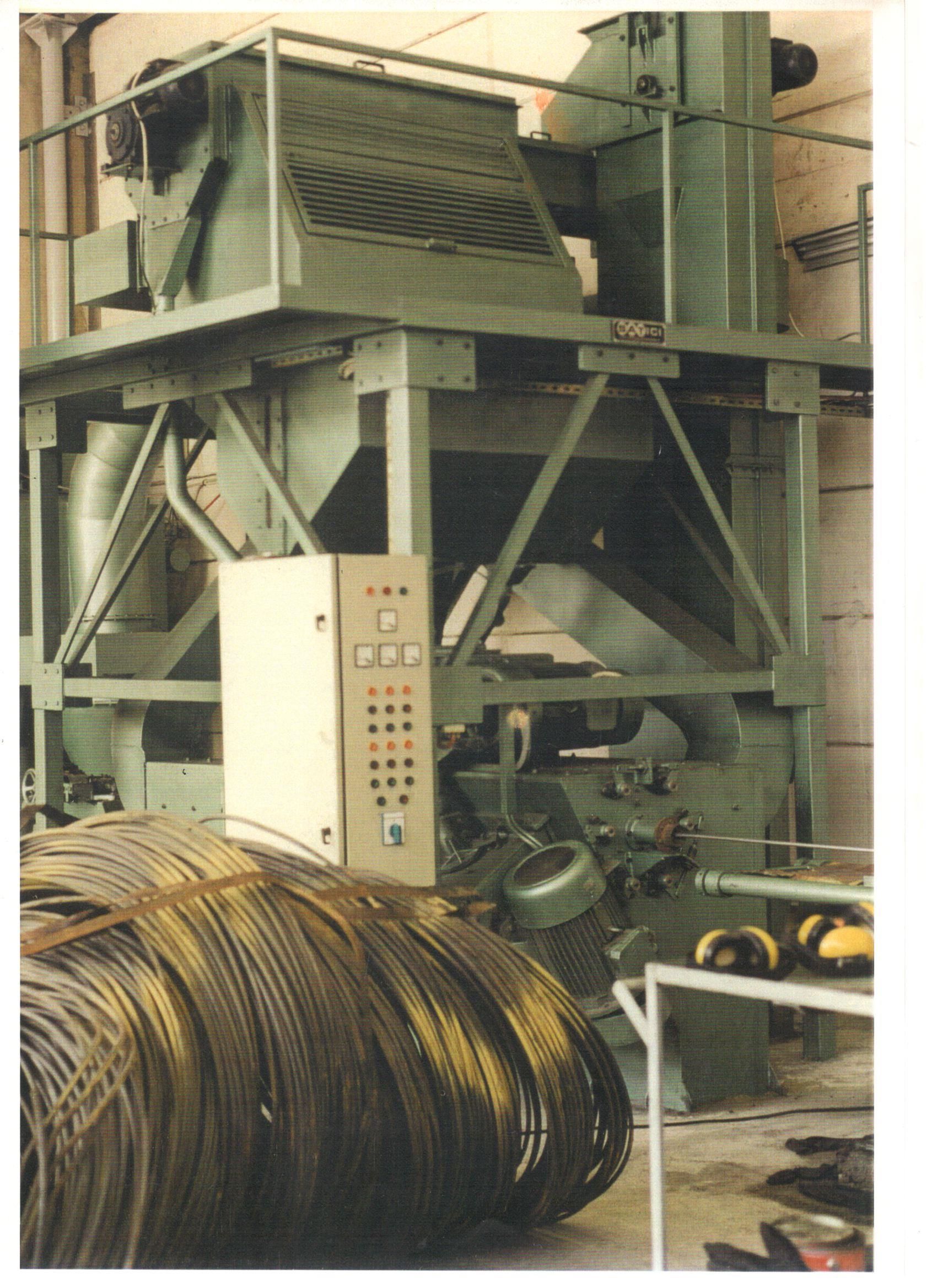

Coil Wire Sandblasting Machine: The Coil Wire Sandblasting Machine is used for cleaning coiled wires. Used in wire production facilities, metal processing industry, and automotive sector. Ideal for cleaning and surface preparation of wires.

Wheel Sandblasting Machine: The Wheel Sandblasting Machine is designed for cleaning and preparing automotive wheels. Used in automotive service centers, wheel production facilities, and maintenance workshops. It enhances the aesthetic appearance and performance of wheels.

Pressure Sandblasting Machine: The Pressure Sandblasting Machine is used for surface treatments with high-pressure abrasive flow. Used in metal factories, automotive parts production facilities, and heavy industry. It effectively cleans contaminants from surfaces quickly.

This product range from SATMAK Makina provides comprehensive solutions for industrial needs, ensuring high efficiency and quality across various sectors.