BOZOK MAKİNA MODEL HAVACILIK SAN.VE TİC. LTD.ŞTİ

Istanbul / Türkiye

About Us

A Necessity for Precision and Efficiency with Bozok SFM Advantages

Shrink fit machines are essential tools for manufacturing companies aiming to maximize their efficiency, quality, and productivity. By utilizing heated tool holders, these machines leverage the principle of thermal expansion to securely grip cutting tools, ensuring precise and powerful clamping.

The process of hot passing involves heating a material with a hollow diameter, causing it to expand and increase its inner diameter. This allows for the insertion of a larger diameter material with a lower coefficient of expansion. As the heated material cools, it contracts, firmly gripping the inserted material.

Shrink fit holders are among the most efficient holder types available, and despite common misconceptions, they are not a luxury but a necessity. While different holders offer various advantages, no single type can be considered universally superior or inferior. Each holder type has its unique characteristics, and a well-equipped machining facility should have access to a variety of holders for optimal performance.

Conscious manufacturers understand the importance of using the appropriate holder for the right application, leading to increased efficiency and quality. As employees of Bozok Machine Model and Aviation Company, we strive to utilize all kinds of holders under the appropriate conditions to elevate our manufacturing capabilities to the highest level.

Bozok SFM offers a range of advantages, making it a superior choice for manufacturing companies:

- Completely domestic, with 95% national product composition.

- Warranty, service, and spare parts support.

- Harmless to human health, user-friendly, and practical.

- Up to 90% energy savings compared to commonly used products and up to 50% compared to our closest competitor, making it environmentally friendly.

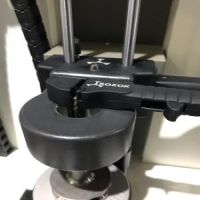

- Precise and practical tool clamping using patented and proprietary special production pliers.

- The ability to heat and cool holders of all types and brands, and long life usage of thin-walled holders. The V3 model supports cooling up to 5 tool holders simultaneously.

- Unlimited consecutive heating without any restrictions.

Bozok SFM was designed and produced by drawing from real-world experiences in machining, rather than merely relying on theoretical assumptions. By combining academic studies with practical experiences, Bozok Machine Model and Aviation Company employees have positioned themselves as both manufacturers and users, enabling them to develop high-featured, user-friendly, reliable, and environmentally friendly machines that cater to the needs of workshops and factories.

In conclusion, shrink-fit machines are indispensable tools for companies aiming to achieve precision and efficiency in their manufacturing processes. By employing the right type of holder for each application, manufacturers can maximize productivity and ensure high-quality outcomes. Bozok SFM's advantages make it a top choice for businesses looking to improve their manufacturing capabilities while prioritizing the user, nature, and human well-being